Modern technology has changed the face of the medical industry. Manufacturers have a lot of opportunities and greater responsibility as new devices can save lives and improve patient care. Medical device prototyping manufacturing can be very profitable, but it must also meet higher standards.

1. Improving Patient Safety

Safety is the main purpose of medical device prototyping. Manufacturers who rush to produce a product could be exposed to risks that they don't know about. These potential dangers can be highlighted by testing prototypes before production.

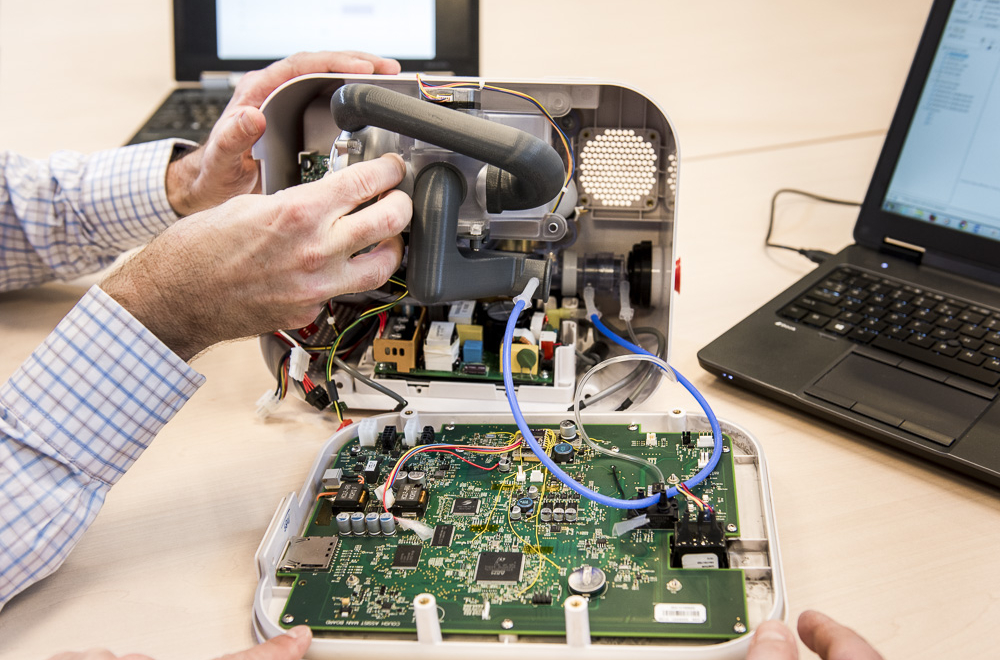

Image Source: Google

In the first quarter of 2018, there were 208.5 million recalled medical devices. This represents a significant financial loss for manufacturers as well as a serious threat to users of these devices. One study found that medical devices have been responsible for more than a 1.7million injuries since 2008.

2. Minimizing Costs

It is possible to keep manufacturing costs low by prototyping medical devices. They may appear counterintuitive at first. The process can slow down time to market and could lead to redesigns that "waste" material. You may not know that prototypes are not only a way to find design flaws, but also the best production methods.

You'll discover which production methods are more cost-effective or less expensive as you create new prototypes. Prototyping can reveal whether the initial design is cost-effective. The manufacturing process can be adjusted and refined just as you did with the product design.